Where do you start?

Great question… it depends.

With mining occurring in such a broad range of commodities, geological domains, operational styles, market conditions, fleet compositions and production targets, it’s hard to know where to start. When it comes to existing operations, the further ahead you can look and prepare, the less burden of decision making is placed on the people who don’t have the tools or resources to know what is going on in the future, or how their decisions will impact the ability to execute the big picture.

When people find themselves in firefighting mode, they spend all their time looking at their feet, trying not to trip over. What they really need is the space to look upwards and outwards to see what obstacles are ahead, allowing them to change course early to navigate their way through it. A clear, well thought out plan allows everyone in the decision-making process to make, informed, thoughtful, calculated and decisive choices.

So how do you provide that guidance?

Start with defining the scope. Understand what the likely obstacles are, look up and look out. This starts with listening and observing. In every workplace, there are people who are doing the grind and they all have questions. Let them ask those questions. You don’t need to know the answer, but in every context, there is an answer and the path to teasing out the answer is where GMEK can help.

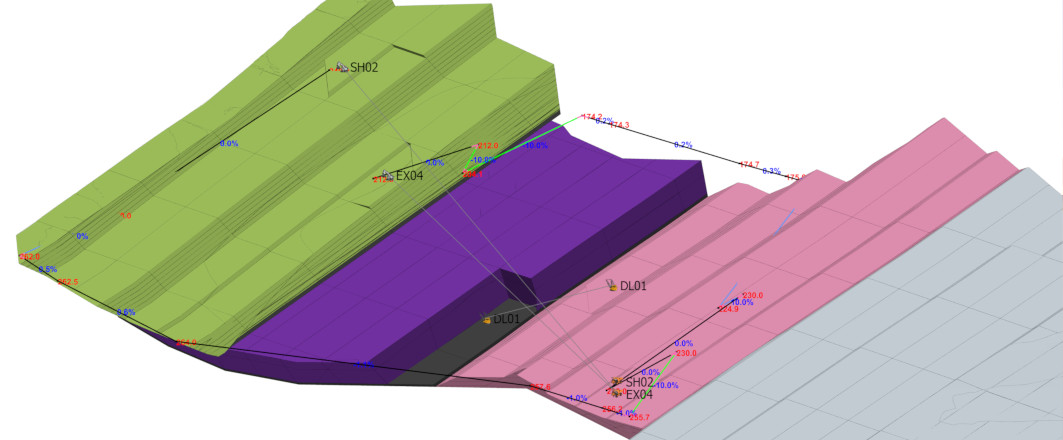

Starting at the resource level, you need to know what you have, where the value lies and what it is that you want to achieve with it. Whether it be a long-life asset or a short lived? high value reserve, having a clear understanding of the value gives clear direction to developing the plan.

The scale of the resource gives clear direction to the capital strategy. Labour market and supply factors can feed into the equation and the ability to weigh up the options is critical to nailing the strategy. Self-reflection and re-evaluation along the way can lead to refinements and you should never be afraid to make a change if it is the right thing to do. Data inputs from the exploration program, market conditions, global stuff (IYKYK) can always drive the need for change, but this needs to be managed at a strategic level – you can’t make a truck driver responsible for making decisions about how they operate their truck, in order to fix global supply chain deficiencies.

Dealing with distractions

Allow everyone in the team the autonomy to their job as good as they possibly can, even allow them to think up and out to the bigger picture, but don’t expect them to drive the truck harder, because the business is under pressure from international trade sanctions.

There has to be a process to interpret the gravity of the pressure point and develop the strategic response so that truckies can be good truckies, supervisors can be good supervisors, or environmental scientists can enviro like no-one has ever done before.

Everyone should be looking up and out to allow them to do their job better, but they shouldn’t be worried about the things that are so far outside their purview, that they can hope to be good at what it is, that we need them to be good at. Don’t think that this intended to keep people down, when truck drivers look up and out, they begin to understand how the whole circuit works. Truckies who look up and out eventually become good dozer operators, dozer operators who look up and out become good digger operators, digger operators who look up and out eventually become good supervisors. But it needs to start with having the autonomy and clear direction, to work out how to do the task at hand, without distracting pressures from outside their wheelhouse. This is when good short-term engineers can become good medium, medium to long, long to pre-feasibility, all through guidance and autonomy.

Join us for part 2 of this installment where we’ll also be tackling:

- Understanding your fleet and what to do with it

- How to extract the value

Written by:

Matthew Carey

Principal Mining Engineer, GMEK